JACO has a clear understanding of what is needed from the plastics industry, ranging from how businesses operate to in-depth engineering designs and applications. For more than 70 years, we have consistently looked for ways to improve plastic parts. JACO has succeeded in developing solutions in new technologies, equipment, and products that have been solid contributors to the industry.

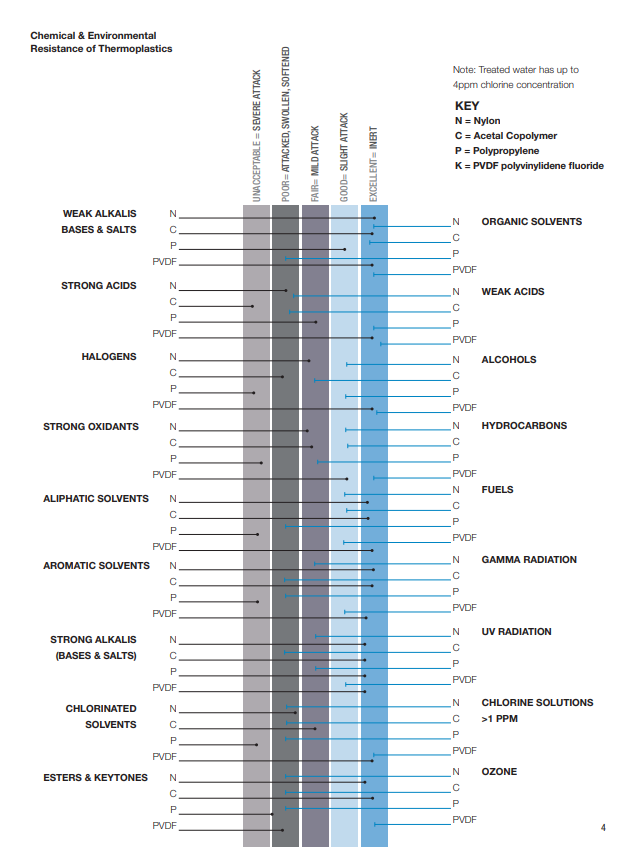

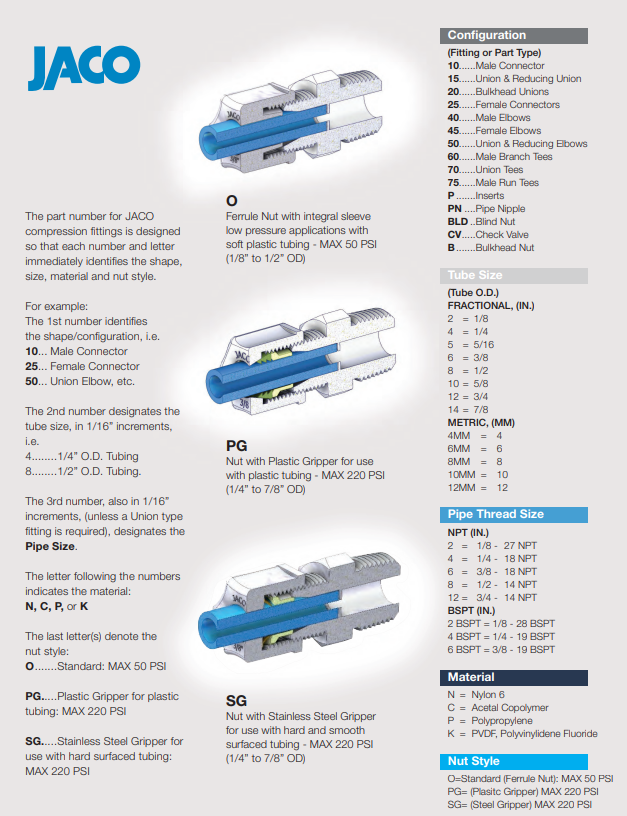

Compression type metallic fittings have a loose ferrule, requiring extra assembly. With the JACO Ferrule Nut (O-Nut), JACO has been able to mold the sleeve as an integral part of each nut, eliminating the need for a two-piece assembly. Although metal fittings were originally developed for copper tubing, additional fittings were later engineered with plastic grippers for plastic tubing. This then led to stainless steel grippers for metal tubing and hard smooth plastic tubing.

Today, JACO fittings are widely used with all types of tubing including copper, plastic, aluminum, stainless steel, and glass. JACO compression fittings are typically less expensive than metal fittings and they offer better resistance to corrosion and chemicals.

Additionally, we offer four different plastic resins for a range of applications dealing with temperatures, acids, and chemicals. JACO plastic fittings provide the following additional advantages:

- Exceptional electrical insulating qualities, which eliminate electrolytic action that usually corrodes tubing when dissimilar metal meets a fitting.

- The ability to absorb mechanical and acoustical vibrations because of the low density and softness of plastic.

- An inherently low resistance to flow, due to smooth internal

- A resistance to scale buildup.

JACO fittings are available in size ranges from 1/8″ through 7/8″ tube O.D. in most common figurations, such as: union, bulkhead, male and female connectors, male branch and male run tees, tee unions, and ferrule nuts. Metric sizes are also available on a special order basis. (Contact JACO for available metric sizes).

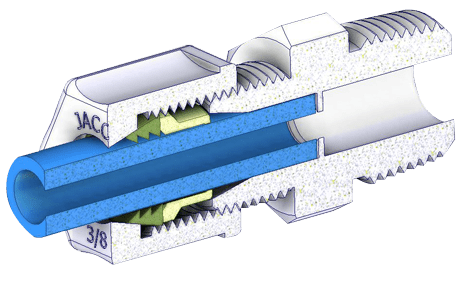

Various resins are used, depending on the application. JACO produces plastic fittings in four different materials: nylon, acetal copolymer, polypropylene, or polyvinylidene fluoride. (PVDF). The fittings can be manufactured in the resins natural color or in black pigment.

Note: Fittings ordered in black are considered a “special” and may require a 1000-piece minimum quantity.

Identifying Jaco Fitting Materials:

1. PVDF is a semi translucent off white color, somewhat translucent.

2. Acetel Copolymer is a shiny white color, smooth slippery shiny white.

3. Polypropylene is a solid opaque white, flat white (most white of fittings).

4. Nylon is an off white almost a very light gray in color, ( a little whiter than PVDF material but not as white as Celcon).

How to Select Materials

JACO tube fittings are manufactured in the following four thermoresins:

(P) Polypropylene: (20% glass filled for improved strength.) Opaque flat white color, (most white of JACO Fittings). Material temperature rating is -30°F to 225°F. Polypropylene (PP) is a workhorse in the plastics industry. The general physical properties of polypropylene are similar to those of high-density polyethylene, (PE), but PP has a harder durometer and is more rigid. It is also more resistant to environmental stress cracking than PE. Polypropylene (PP) is light weight and high in chemical resistance. It is unaffected by alkalis (bases), salts and most weak acids, (particularly hydrochloric and phosphoric acids). Below 175°F it has good resistance to organic solvents. It is not suitable for oxidants, strong acids, chlorinated hydrocarbons, high concentrations of free chlorine, and aromatic compounds (such as benzene and toluene). PP is very inert, thus popular for high purity applications such as deionized water, etc. Avoid use in continuous sunlight. N.S.F. 14 certified, N.S.F. 61 compliant. Tensile Strength of 4,500 psi increases to 6,400 psi with glass fill. Durometer = 70D to 80D, (Autoclavable – yes).

(N) Nylon 6: Nylon 6 is an off-white, very light gray colored material (a little whiter than PVDF material, but not as white as Acetal). Because of Nylon’s versatility it is one of the most widely used thermoplastics. Nylon 6 is a tough, strong, abrasion-resistant material with excellent impact resistance, both single and repeated. The material temperature rating is between -40°F to 250°F, and it has good strength at high temperatures. Since Nylon naturally absorbs water it is typically not preferred for wet applications. Moisture acts as a plasticizer, reducing tensile strength and stiffness, and increasing elongation. However, as moisture content rises, significant increases occur in impact strength and energy absorbing characteristics. Dry state properties will return as the material dries out. Nylon has good chemical resistance to organic solvents, oils, hydrocarbons, and fuels. Nylon 6 has poor chemical resistance to strong acids and bases. It is not recommended for use with ammonium, boric acid, calcium, sulfuric acid, or hydrochloric acid. N.S.F. Listed. F.D.A. Listed. Tensile Strength = 8,800psi, Durometer = 75D to 90D. (Autoclavable – No).

(K) PVDF (Polyvinylidene fluoride): PVDF has a semi translucent cloudy off-white appearance. It is superior to other fitting thermoplastics in abrasion resistance and chemical resistance for handling highly corrosive fluids. It has remarkable strength over the largest working chemical range. The material is rated at -80°F to 275°F and has a working temperature range for fittings of -40°F to 250°F. PVDF’s impact strength is over twice that of PVC, and is extremely durable and abrasion resistant under mechanical abuse. It also has outstanding aging resistance, with its properties remaining constant after many years. PVDF also has remarkable fire resistant properties. In the Underwriter’s test PVDF was given the highest classification (V-O), indicating that it was non-flammable and self-extinguishing. PVDF has excellent chemical resistance against strong inorganic and organic acids, aliphatic and aromatic hydrocarbons, and halogenated solvents such as chlorine and bromine. PVDF is not suitable with fuming sulfuric acid, concentrated alkalis, hot bases or bases having a PH >12. For any chlorine containing compound, the material does not need to be blocked from UV. The UV itself will not break down in the material, nor will the chlorine. The UV will pass right through the PVDF resin, the UV will then attack the chlorine and make the chlorine more aggressive due to free radicals. This can attack the PVDF material quicker. PVDF is FDA compliant, absolutely non-toxic and can be used in repeated contact with food products. N.S.F. Listed. Tensile Strength = 5,900 psi. Durometer = 75D. (Autoclavable – yes).

(C) Acetal Copolymer: Acetal has a glossy, slippery white appearance that may yellow over time. It has high tensile strength and good wear resistance over a broad range of temperatures. The material is rated at -40°F to 200°F in open air, and rated for 180°F in hot water applications. Not affected by continuous hot water service and works smoothly with metal and hard surface tubing.

Note: Acetal copolymer cannot be recommended for continuous exposure to solutions with a chlorine concentration greater than 1 ppm. (Many water treatment facilities use up to 4 ppm of chlorine concentration.) Acetal is unaffected by formaldehyde, oil, alcohols, and most inorganics. However, it is not recommended for use with acids. Good resistance to methylethylketones and has low moisture absorption rate. Listed by U.S.D.A and F.D.A. for use with coffee, milk, and antibiotics. Also N.S.F. Listed. Should not be continuously exposed to sunlight (UV). Tensile Strength = 8,800psi, Durometer = 90D to 95D. (Autoclavable – No).

Note: These chemicals and environmental resistance ratings for thermoplastics are provided for comparison purposes only. No assurance can be implied that any compound will meet the ratings listed. End users should conduct their own evaluation of compounds to ensure satisfactory compatibility with any environmental or physical conditions to which they may be exposed.

Chemical & Environmental Resistance of Thermoplastics

No information supplied by JACO Manufacturing Company constitutes a warranty regarding product performance or use. Any information regarding performance or use is only offered as suggestion for investigation of use, based upon JACO or other customer experience. JACO makes no warranties, expressed or implied, concerning the suitability or fitness of any of its products for any particular purpose. It is the responsibility of the customer to determine that the product is safe, lawful and technically suitable for the intended use.

Operating temperatures of JACO Tube Fittings are regulated by ambient and fluid temperatures, type of fluid being carried, tubing type, and conditions of mechanical abuse. Temperatures listed are designated as material ratings only. Testing of complete fitting in customer application is recommended.

Installation Instructions

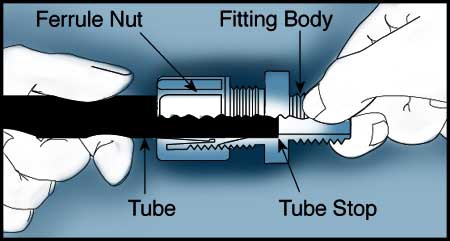

- Cut the tubing end squarely and remove the internal and external burrs.

- Insert the tubing through the back of the nut all the way through the nut assembly to the tube stop in the fitting body (see illustration).

- While holding the tubing firmly against the tube stop, hand tighten the nut.

- Wrench tighten the nut 1½ to 2 additional turns.

- All nuts must be retightened when the system reaches projected operating temperature.

Caution: To ensure proper assembly, tubing MUST be fully inserted into the fitting body to the tube stop.

NOTE: It is not necessary to disassemble this fitting for application. Merely insert tubing to stop and tighten nut.

Notes on Installation

- If the tubing does not enter the nut easily, loosen the nut one turn and then insert the tubing all the way to the tube stop in the fitting body.

- It is not necessary to disassemble this fitting for application. Merely insert tubing to stop and tighten nut.

- Squeaking sound when tightening nut is normal. For NPT pipe threaded connections, PTFE Pipe Thread Sealant or PTFE Pipe Seal Tape must be used.

- With metal tubing, deburr and clean outside of metal surface engaged by the fitting with steel wool. Finish cleaning prepared surface with denatured alcohol.

Safe Product Selection

When selecting a product, the total system design must be considered to ensure safe, trouble-free performance. Function, temperature, material compatibility, adequate ratings, proper installation, operation, and maintenance are the responsibilities of the system designer and user.

Caution

Do not mix or interchange parts with those of other manufacturers. Our parts are designed specifically to be used only with other JACO compression fittings.

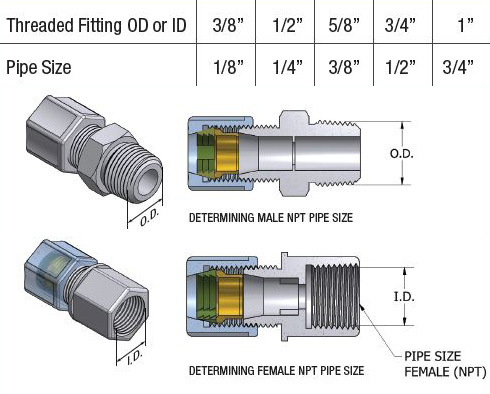

Please read before ordering: Pipe size is the accepted industry designation, not the actual measured size. To determine pipe size, first use a measuring device to measure the outside diameter (OD) or inside diameter. (ID), as shown in diagram at right. Then round to nearest dimension listed in the chart and select the corresponding pipe size.

Note: Fitting dimensions as described in this brochure may not reflect running changes made to improve part performance. Check with JACO Manufacturing Company in critical applications. Dimensions are in inches. Select metric sizes are available.

* Operating pressures of JACO Tube Fittings are regulated by ambient and fluid temperatures, type of fluid being carried, tubing type, and conditions of mechanical use. Temperatures listed are designated as material ratings only. Pressures in excess of above specifications in all fitting sizes should be tested by the customer in their particular application.

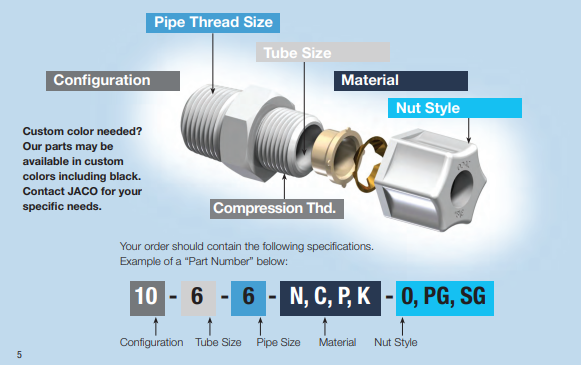

Note: It is not necessary to designate the nut size when ordering complete units as this will be determined by the tube size indicated in the part number.

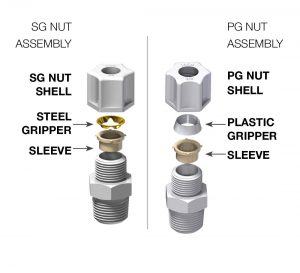

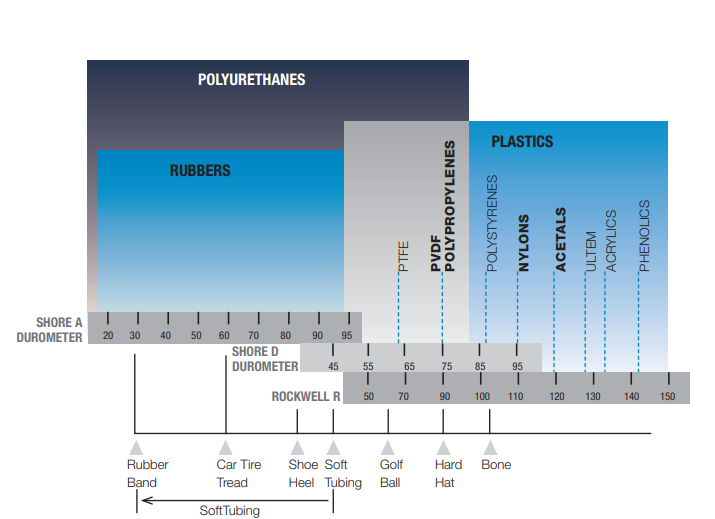

Note: JACO Manufacturing Company does not supply tubing. We manufacture compression tube fittings that work with many different types of tubing from soft plastic, hard plastic, metal, glass, ceramic, and exotic alloys. Our fittings are designed and sized to fit the outside diameter of the tubing. It is the customer’s responsibility to select the appropriate JACO material and nut style to work with their typical application and environment. A key factor in selecting Jaco fitting Nut Types is the Durometer of the tubing. The Gripper component material in the JACO Nut should be slightly harder, if possible, than the tubing it is connecting, to ensure optimum grip in the connection.

Hardness Comparison Chart

This document found below is an information guide to help educate the public about the different types of JACO compression nuts used with JACO compression fittings. It may also be used to show proper orientation when assembling the three piece nut components.

Prices are subject to change based on market conditions.